“Zip-O-Lam was the only laminator that could offer timely delivery of 12 1/4" beams with full face lams. This capability played an integral role in the success of this project.”

Jordan Donahue | RLD Company, Inc

GLULAM Highlights

- 12 1/4″ in depth Beams

- Special 2×14 lamstock

- 50-foot composite beams

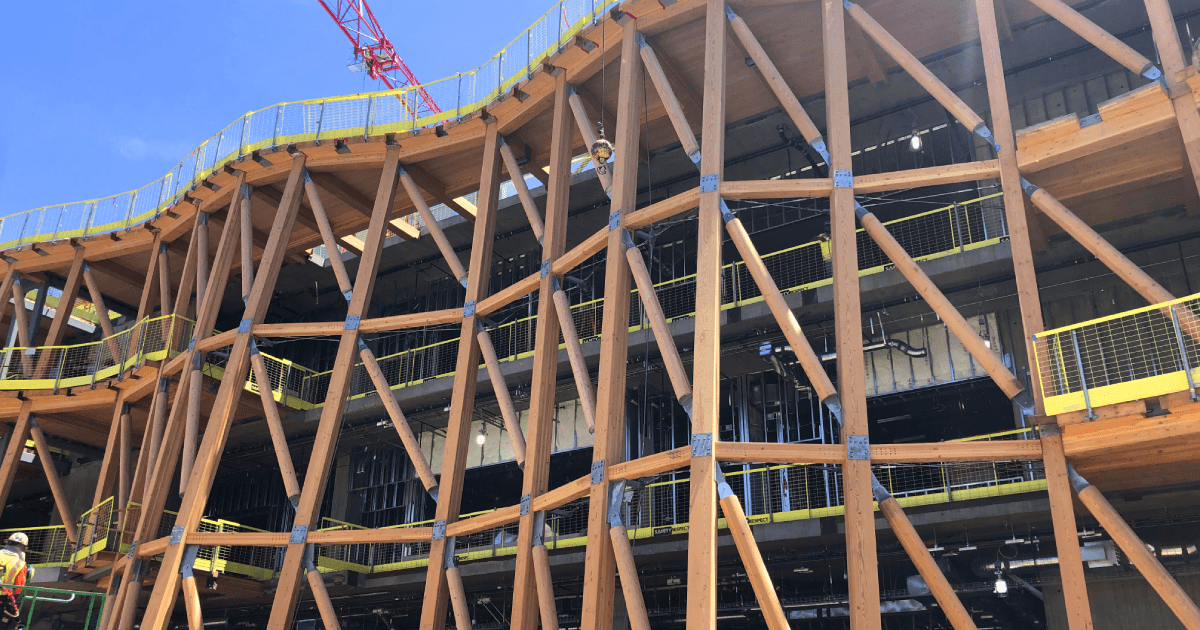

The Caltech Resnick Sustainability Center aimed to create a visually striking and structurally sound lattice-like curtain wall that would highlight the natural beauty of mass timber. The architectural and design team envisioned a glulam structure composed of beams, columns, and diagonal braces, each uniquely shaped to wrap around the north and west corners of the building. This ambitious design required every glulam component and connection to be custom-made, with no two pieces identical.

Project Design and Implementation:

Zip-O-Laminators’ ability to produce beams with full-face laminations was essential in achieving the clean, uninterrupted wood surfaces that the architects wanted to showcase. These beams, measuring 12 1/4″ in depth, provided both structural strength and an appealing visual element. To maintain the desired look of solid-sawn wood without visible seams or grooves, Zip-O-Laminators manufactured wider, custom-cut 2×14 lamstock for the faceboards RLD Company partnered with Zip-O-Laminators due to their shared history and trust in producing high-quality glulam beams. This collaboration was essential for the project’s success.

Challenges & Solutions

The primary challenge was producing beams wider than typical 2×12 materials, which required innovative solutions.

Zip-O-Laminators adapted their finger jointing process to accommodate 2×14 lamstock. The project also demanded columns of varying lengths, including some 50-foot beams with full-face laminations on both sides.

Challenges included:

- Custom Geometry: The unique shape and varying dimensions of the curtain wall necessitated that each glulam component be distinct, creating significant complexity in manufacturing and assembly.

- Precision and Timing: Ensuring the correct fitment of all components during the on-site assembly, in line with the construction schedule, was crucial.

- Material Quality: Maintaining aesthetic quality by producing glulam beams with full face laminations to avoid visible seams and pitch pockets.

Results

The custom glulam beams enhanced the project’s aesthetic appeal significantly. The client’s design vision was fully realized with beams that combined structural integrity and a beautiful finish. The collaboration between Zip-O-Laminators and RLD ensured a successful project completion, meeting all specified goals.

Beam Specs

The glulam beams featured 2×14 wide face laminations, providing a seamless, aesthetically pleasing appearance. Both shorter columns and 50-foot beams were produced with full-face laminations. The beams were designed to meet the structural requirements while maintaining the desired wood-centric aesthetic of the building.